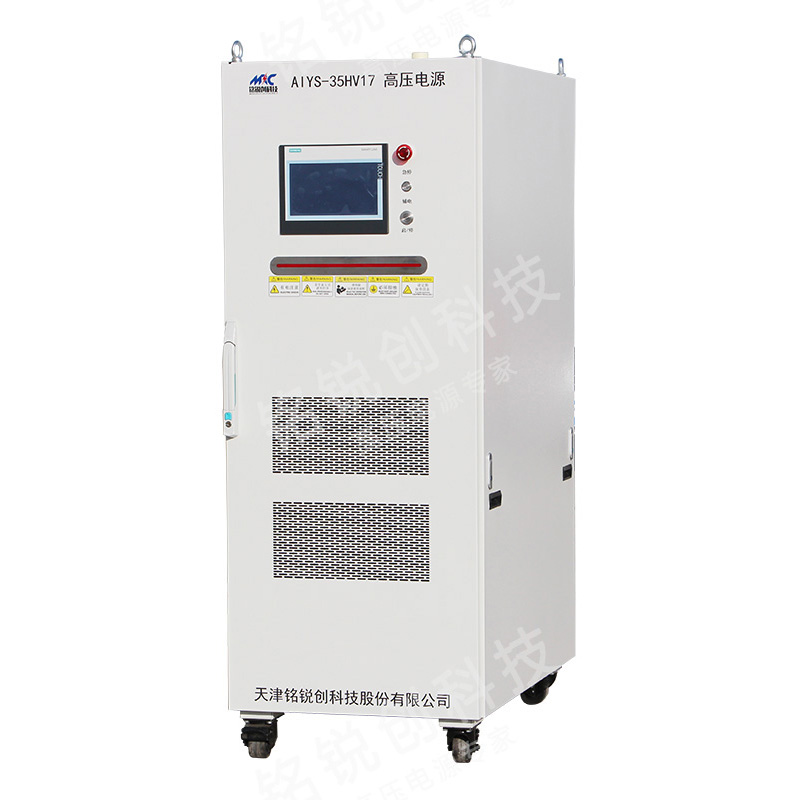

Features

1. The output of the high-voltage power supply system configured with EB furnace is one high-voltage power supply output

2. The high-voltage power supply system configured with the hot gun integrates the main high-voltage power supply, filament power supply and auxiliary high-voltage power supply

3. The high-power high-voltage power supply adopts the high-frequency inverter zero-voltage full-bridge switch technology above 20kHz

4. Filament current and sub-high-voltage voltage sampling are directly measured and sampled at high potential and transmitted to the control system through optical fiber isolation

5. All output values of high-voltage power supply can be continuously adjusted from 0 to 100%

6. The high-voltage power supply can withstand harsh working environments such as discharge, short circuit, and arc pulling for a long time

7. The high-voltage power supply has local mode and program control mode, of which the local mode includes: touch screen setting and high-precision ten-turn potentiometer, and the program control mode includes: 0-10V analog control and host computer software setting.

8. High voltage 10-50kV (customized according to user requirements)

9. The output power of high-voltage power supply is 100-800kW (customized according to user requirements), which can meet the of different application fields

10. The maximum filament current is 50A (customized according to user requirements)

11. The maximum sub-high voltage voltage is 1500V-2000V (customized according to user requirements)

Unique technology

1. Protection time: When the sensitive current detection circuit detects that the current exceeds the protection set value, it immediately starts the current limiting power control circuit to ensure that the output current is controlled within the set value. The protection start-up time is within 10us.

2. Redundancy technology: the power supply system can be arbitrarily cut off at any time without affecting the stable operation of the entire power supply system under the condition of configuring redundant machinery and equipment.

3. Module design: The high-voltage power supply system adopts modular design, 100kW is a standard module, the pre-stage inverter and the post-stage rectification are independent of each other, and the installation is simple and the maintenance is convenient.

(1) Input voltage: AC380V±10%, 50Hz±10%

(2) High-voltage power supply

Output voltage: 50kV (customizable)

Output voltage stability: <0.2%

Ripple: < 0.5%

Current: Determined by the output power, the maximum can be 800KW (customized)

Current stability: <0.2%

(3) Filament power supply

Output current: DC 10A, 20A, 30A, 50A (customizable)

Output voltage: determined by filament load, power not exceeding 3kW

Filament current stability: < 0.2%

(4) Sub-high-voltage power supply

Output current: 10mA max.

Output voltage: DC 1500-2000V (customizable)

Output voltage stability: <0.2%

Output voltage ripple rms: <0.3%

(5) Short-circuit sealing time: ≤10uS.

(6) Short-circuit voltage recovery time: 1mS (can be adjusted according to user requirements, the shortest time is 1mS)

(7) Power supply efficiency: ≥95% (measured at 80%~100% rated output)

(8) Power factor: cosΦ = 0.95

(9) Power supply protection mode: over-voltage, over-current, over-temperature, phase loss, discharge detection

(10) Parameter setting:

Local control: high-precision ten-turn potentiometer, touch LCD screen setting

Remote control: The power supply has a communication interface (RS232/RS485 either), which can be connected with a PC for remote control.

(11) Working mode: It can work continuously at full load for a long time

(12) Cooling method: water-cooled

(13) Working environment temperature: -20 to 40 degrees Celsius

(14) Working environment humidity: less than 90% and no condensation

(15) Power supply dimensions: 400kW (width: 1300mm depth: 1000mm height: 2000mm) according to different power, the size will change

High voltage power supply

High voltage power supply

High power high-voltage DC power supply

High power high-voltage DC power supply High voltage capacitor charging and discharging system

High voltage capacitor charging and discharging system High voltage power supply for electron accelerator

High voltage power supply for electron accelerator Electric arc furnace power supply

Electric arc furnace power supply Electron gun high voltage power supply

Electron gun high voltage power supply Electron beam welder power supply

Electron beam welder power supply Type E electron gun power supply

Type E electron gun power supply Evaporative coating power supply

Evaporative coating power supply High-power DC power supply

High-power DC power supply Regenerative bidirectional DC power supply

Regenerative bidirectional DC power supply